mills

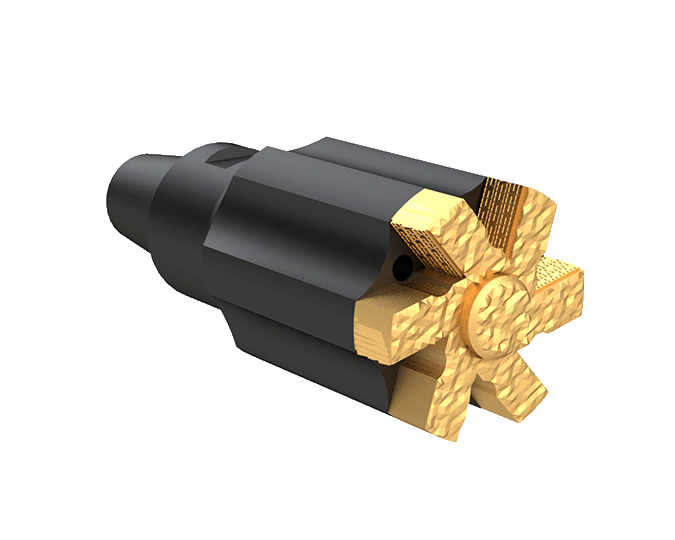

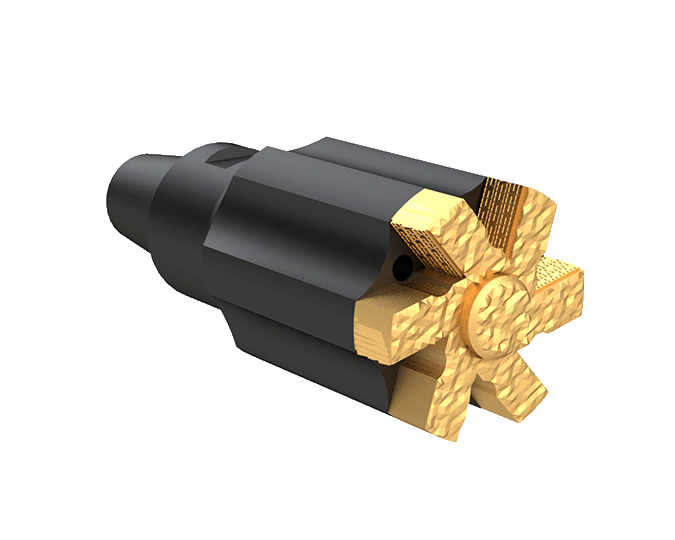

flat bottom and bladed junk mills

The Junk Mill dressed in Tungsten Carbide mills its way through the toughest drilling materials. It is often said to be the true workhorse of downhole milling operations.

Use Junk Mills to mill almost anything in the hole.

Available Sizes: O.D.- 1.75” – 27.00”

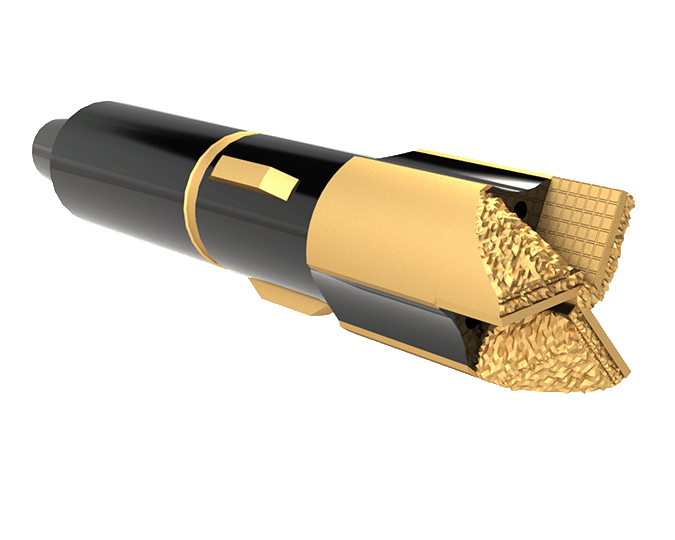

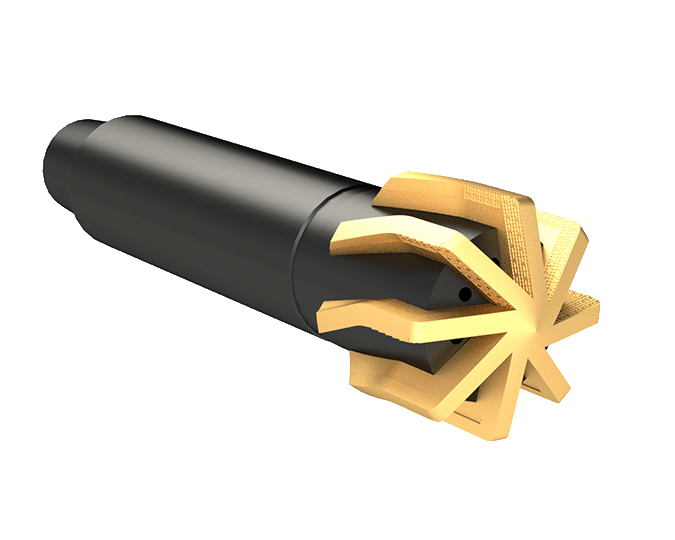

taper mill

The PGI Taper Mill allows milling of restrictions in collapsed casing or liner sections, and dressing of whipstock windows, and can be placed ahead of other milling and fishing tools.

Features, Advantages, and Benefits:

- Dressed in Crushed Carbide Matrix to provide excellent milling performance and longevity.

- Carbide-dressed blades mill the section to full mill diameter

- Large circulation ports and oversized water courses enable debris removal for conventional milling and reverse circulation.

Available Sizes: O.D. -1.75” to 36.00”

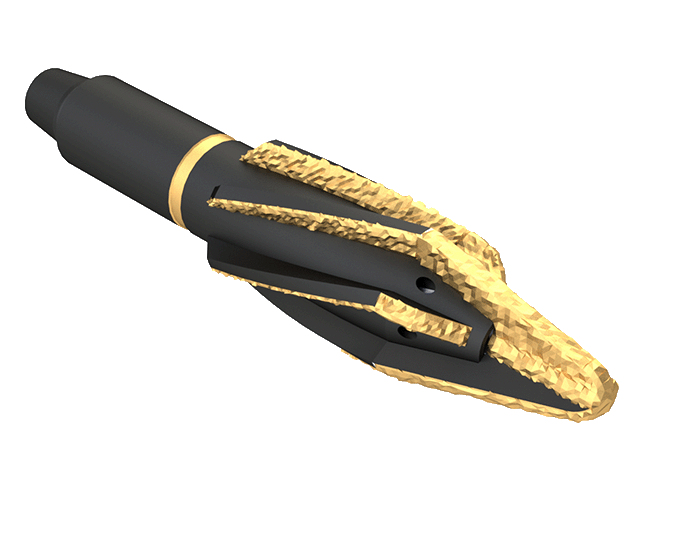

pilot mill

PGI Pilot Mills is best used for milling stuck tubular, such as liner, liner hanger, wash pipe, rotary shoe, or drill pipe. During milling, the pilot assembly keeps the tubular centered while the milling blades remove the product.

Available Sizes: O.D. Sizes on request

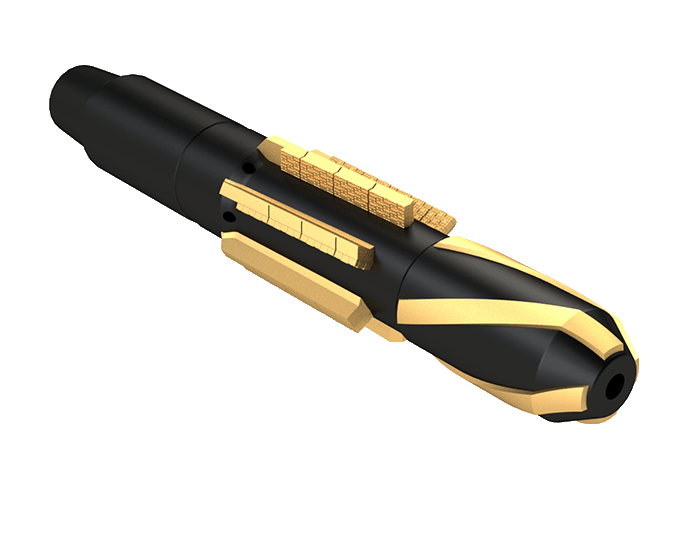

watermelon mill

PGI Keyhole Watermelon Mill allows collapsed casing and liners to be milled and provide window clean-up milling in Whipstock applications.

Features, Advantages, and Benefits:

- Mill has a tapered top and bottom to allow reaming in both directions.

- Utilizes the latest carbide technology for cost-effective performance.

- Mill dressed to enable it to be run with either connection up.

- Mill Blades are wrapped to give full 360° coverage.

- Run in tandem with Window Mill to perform clean-up run in Casing Exit operations.

- A full range of standard mill sizes is available.

- One-off customer-specific sizes are available on request.

Available Size: O.D. – 4-3/4” – 36.00”

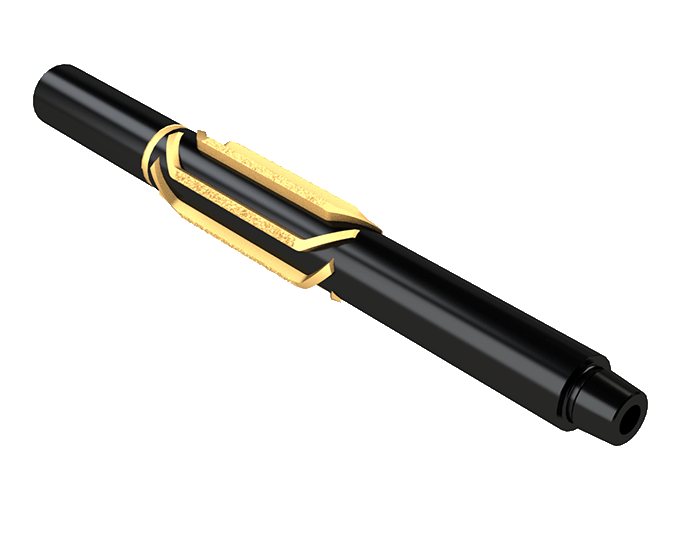

string mill

PGI string mill is used to clean out casing and whipstock windows.

Features, Advantages, and Benefits:

Short Trailing and leading angles, allow the mill to clean “Birds nest” and other obstructions in the string.

Assures milled section maintains full gauge.

Available in various API & Premium Connections.

Available Sizes: O.D. -2.75” to 24.00”

econo mill

PGI Eco-mills are low-cost mills for milling tubular equipment. Additionally, it can be used for milling bridge plugs and retainers or removing cement from drill pipes in tubings.

Features, Advantages, and Benefits:

- Can be easily shipped

- Low cost

- Flow ports allow good circulation.

- Available in various connections and sizes.

Available Sizes: 3.50” – 12.1/4” O.D.

window mill

PGI Keyhole Window Mill provides fast and effective window clean-up milling in Whipstock applications.

Features, Advantages, and Benefits:

- Mill design allows for fast effective milling of the windows.

- Utilizes the latest carbide technology for cost-effective performance.

- Mill Blades are wrapped to give full 360° coverage.

- Run with Watermelon Mill to perform clean-up in Casing Exit operations.

- A full range of standard mill sizes is available.

- One-off customer-specific sizes are available on request.

Available Sizes: 3-3/4” – 27”

Let’s Get Started!

Start A New Project Today

Enhance oil and gas operations with ProGrynd’s advanced drilling and production solutions. Partner with us for top-tier services and equipment. Let’s elevate your efficiency together.